Materials

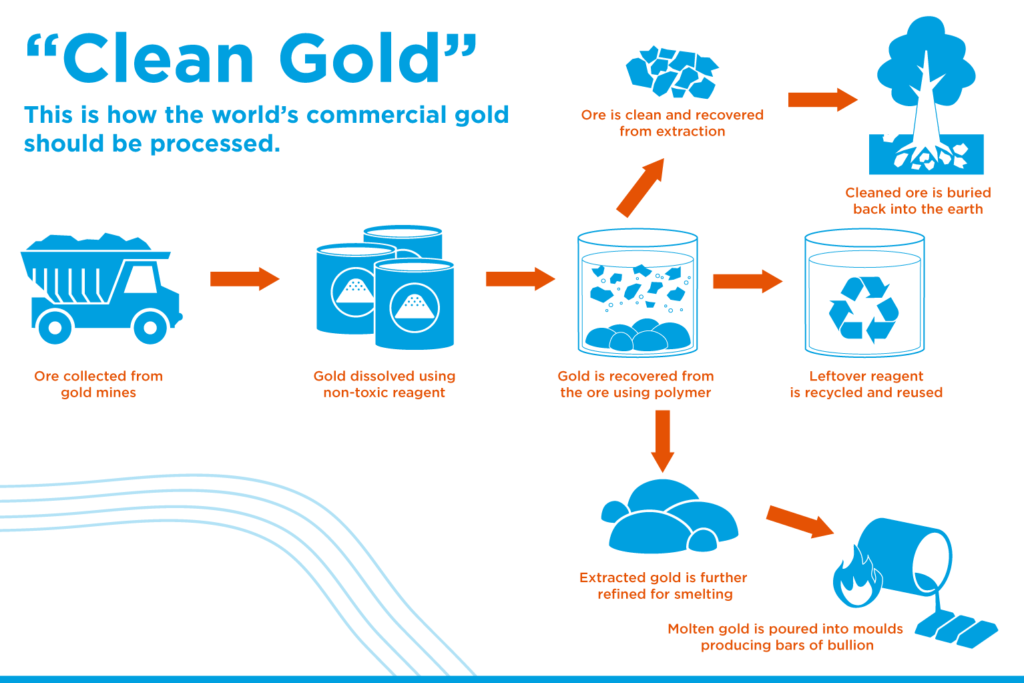

Clean Mining possesses demonstrable capabilities, tested in the field and at scale, for removing cyanide as the primary means of leaching gold in medium to large-scale mining operations.* Recently, the same solution for removing cyanide has been proven to fully replace mercury use in the artisanal and small-scale mining sector.

This alternative leaching solution is unique in its versatility and scalability—capable of being applied to a wide range of gold-bearing ores encountered by different operators. Non-toxic, non-flammable and water soluble, the gold recovery agent’s success rate in leaching gold from certain ores—e.g. carbonaceous—is 50% more compared to cyanide.

*DOWNLOAD our Gold Validation Document here >

Future Development

Following the launch of the solution in mid-2019, Clean Mining has been inundated with interest from across the world.

As market adoption grows, the ability for miners to access Clean Mining technology will expand, as will retailer and consumer access to Clean Gold™.

With certification, branding and provenance already built into Clean Gold™, gold producers, manufacturers and jewellers will readily enjoy the transparency, economic incentives, sustainability credentials and prestige that come with being part of a Clean Solution.